Semiautomatic and automatic coiling solutions for HDPE sizes within the range 16mm to 250mm diameter.

Introduction

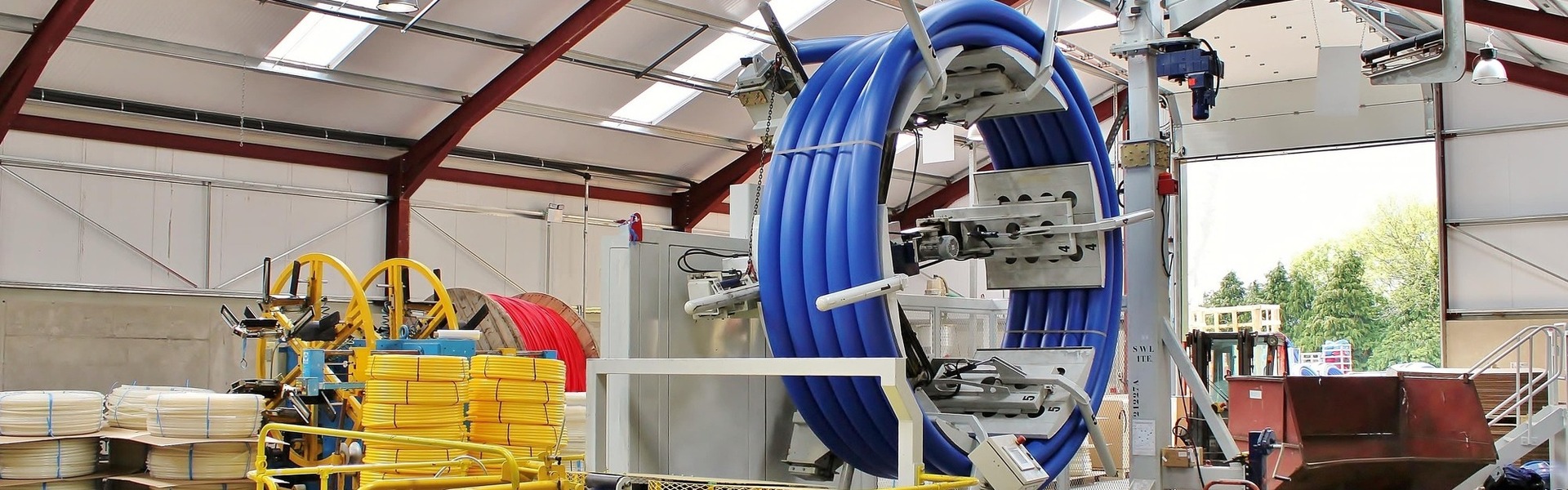

We provide semiautomatic or automatic coiling solutions for HDPE sizes within the range 16mm to 250mm diameter. Automatic machines take pipe directly from the extrusion line, form it into the desired coil shape and apply restraining packaging, such as PET straps or stretch film wrap, before unloading the completed coil. Semiautomatic machines also coil pipe directly at the end of the extrusion line, however they require an operator to perform a number of functions such as connecting the pipe end to the coiler, applying packaging and initiating or performing coil unloading.

For pipe diameters from 16mm to 40mm we also offer complete offline coiling systems which typically provide the most economical option for coil production in factories where there are multiple extrusion lines producing pipes within this diameter range.

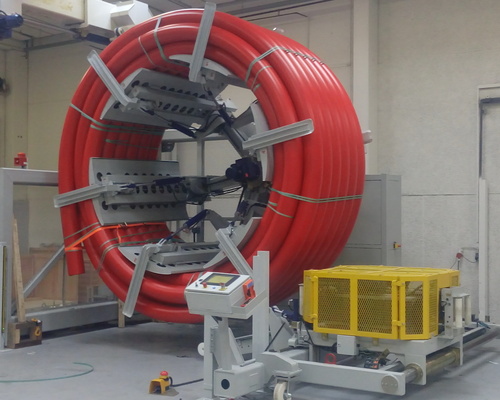

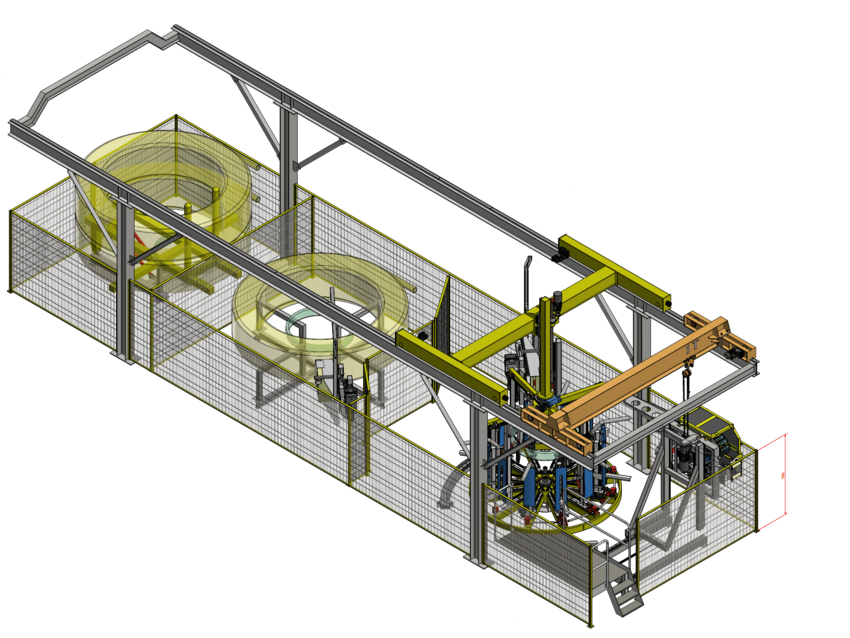

Fully automated coiling equipment for 63mm to 180mm HDPE pipe - AHCS (Automatic Horizontal Coiling System)

This new range of machines is unique in the market and has been developed to offer FULL AUTOMATION of coil production, including pipe end engagement, coil layering, application of restraining straps (intermediate and final layer) and coil unloading. The main benefits of the is system are;

- No operator input required during coiling cycle

- Improved safety over semiautomatic equipment

- Consistent and repeatable coil presentation

- Pipe feed into the coiling machine is continuous, no need to stop pipe movement into coiler during application of straps

- For the larger machines in this range standard specifications includes our "Ovality Reduction Technology" which reduces pipe ovality in the coil and greatly increases the resistance to coil buckling during coil storage.

Semiautomatic coiling equipment for 63mm to 180mm HDPE pipe.

This range of semiautomatic machines offers an economic equipment solution for coiling pipe sizes up to 180mm in diameter. These machines require an operator during each coil cycle to attach the pipe end, apply restraining straps and initiate unloading of completed coils. Beneficial features and options available with this range include:

- One person operation throughout all phases of coil cycle

- Safe and controlled coil production from pipe end connection to coil unloading

- Pipe end attachment using no attachments and no pipe end distortion

- Integrated coil unload device

- Powered coil diameter adjustment

- Robust design and construction for 15+ year life

Coiling machines with "Ovality Reduction Technology"

These semiautomatic machines, incorporating our unique "Ovality Reduction Technology", cover pipe sizes from 90mm to 250mm diameter, with the "Ovality Reduction Technology" being available on pipe diameters over 110mm. Benefits of this range are:

- Pipe ovality is significantly reduced pipe at the point of coiling

- Increased resistance to coil buckling during coil storage and transport

- Enables pipe sizes up to 250mm diameter to be coiled in road transportable coil dimensions

- Enables coiling at reduced coil diameters, giving the possibility of more compact coils, or longer coil lengths

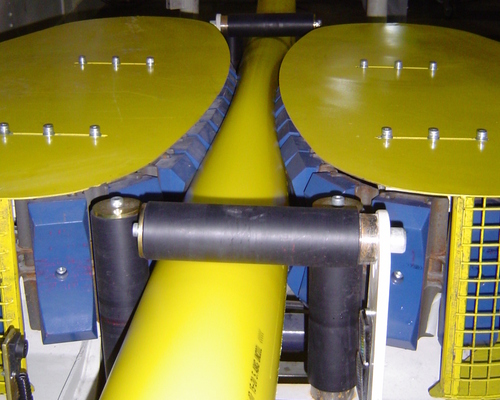

Automatic coiling systems, for pipe sizes 16mm to 40mm.

Our automatic coiling solutions offer an exceptionally efficient method of producing finished coils. These machines are available in single or twin head format, with a choice of coil packaging method; LLDPE stretch film or polypropylene/PET straps, allowing the optimum machine configuration to be selected for each application. Some of the benefits of our automatic coilers are;

- reduced labour costs

- neat and repeatable coil presentation

- may facilitate increased extrusion rates

- Improved operator safety by eliminating operator input from the coiling cycle

These machines can be specified for operation directly on the end of an extrusion line, where coiling rate is matched to the extrusion line speed, or they can be specified to operate in an off-line system where the coil production rate is independent of the extrusion line and can typically reach between 75 to 150m/min, enabling one automatic coiler to handle the pipe output from between two to four extrusion lines. The additional benefits of PCD's Off-line Coiling System are;

- Reduced labour cost, potentially by up to 75% if replacing semi-automatic online coiling

- One automatic coiler can handle the pipe output from between 2 to 4 extrusion lines

- For multiple extrusion line systems the investment cost is usually lower that investing in an automatic coiler for each line

- The task of finished coil production is separated from the extrusion line allowing the efficiencies of the extrusion process and the coiling process to be independently maximised.

An offline system consists of a drum take-up stand for each extrusion line to wind pipe onto bulk storage reels and a high-speed rewind line, which removes pipe from the bulk storage reels and feeds it to the automatic coiler. At the rewind line, the cycle time to produce one coil is between 25 to 90 seconds, depending on coil length and packaging method being used.

Take-up machines for winding pipe onto reels

Our take-up stands wind pipe onto wooden or steel reels at the end of the extrusion line in applications where pipe is to be supplied on reels rather than as free-standing coils. Take-up stands are usually tailored to suit each application, however, common benefits are;

- Wide range of drum sizes can be accommodated

- Compact footprint

- Take-up speed automatically synchronised to the extrusion line

- No operator required during the time taken to fill a drum, which is typically between 6 to 24 hours