Automatic coiling machines provide an efficient and safe method of coiling to length and packaging plumbing pipe.

On-line automatic coiling machines

Our on-line automatic coiling machines provide an efficient and safe method of coiling to length and packaging plumbing pipe. Coilers are available in single or twin head configuration with a choice of coil packaging using either LLDPE stretch film or polypropylene/PET straps. In-line accumulators can also be supplied for higher line speed applications. These coiling systems can be further complemented by the specification of robotic coil unload, automated coil labelling or powered conveyor systems to move coils to desired locations for final packing. Some of the benefits of these automatic coilers are;

- Reduced labour costs

- Neat and repeatable coil presentation

- May facilitate increased extrusion rates

- Improved operator safety by eliminating operator input from the coiling cycle

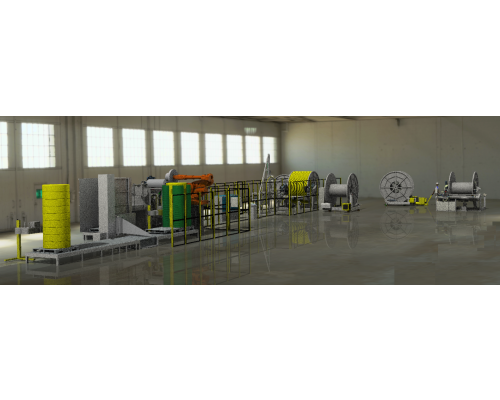

Off-line high-speed coiling systems

These systems allow one automatic coiling machine to handle the output of multiple extrusion lines. An offline system consists of a drum take-up stand for each extrusion line to wind pipe onto bulk storage reels and a high-speed rewind line, which removes pipe from the bulk storage reels and feeds it to the automatic coiler.

The benefits of PCD's Off-line Coiling Systems are;

- Reduced labour cost, potentially by up to 75% if replacing semi-automatic online coiling

- One automatic coiler can handle the pipe output from between 2 to 4 extrusion lines

- For multiple extrusion line systems the investment cost is usually lower that investing in an automatic coiler for each line

- The task of finished coil production is separated from the extrusion line allowing the efficiencies of the extrusion process and the coiling process to be independently maximised.

Coilers for integration into a rewind line are available in single or twin head configuration with a choice of coil packaging using either LLDPE stretch film or polypropylene/PET straps. These off-line coiling systems can be further complemented by the specification of robotic coil unload, automated coil labelling or powered conveyor systems to move coils to desired locations for final packing. At the rewind line, which can operate at pipe transfer speeds of up to 200m/min, the cycle time to produce one coil is between 25 to 90 seconds, depending on coil length and packaging method being used. The overall throughput of our rewind lines is typically between 2 to 4 times the output from a single extruder.