We offer a range of upgrade and refurbishment packages for machines originally manufactured by PCT Ltd in the UK or by PCT Inc in the USA.

PCT Ltd Machines

We offer a range of upgrade and refurbishment packages for machines originally manufactured by PCT Ltd in the UK or by PCT Inc in the USA. PCT manufactured over 400 machines between 1994 and 2015, many of which remain in operation today. Whilst we treat every enquiry to upgrade or refurbish a PCT machine individually, we do offer some common upgrade/refurbishment packages, as below;

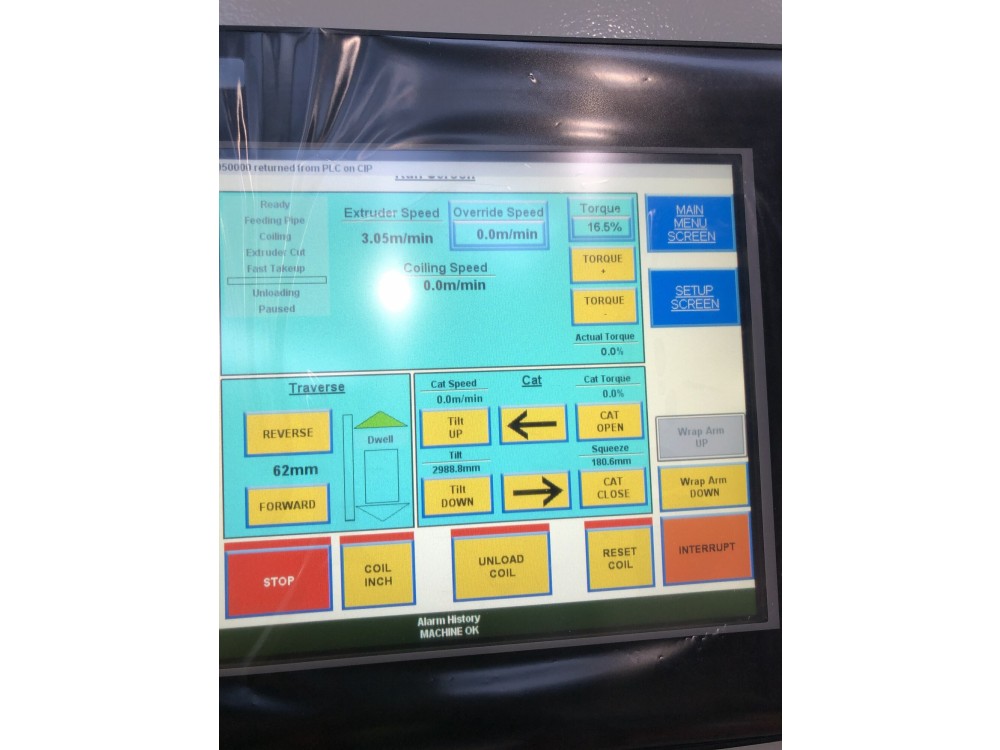

Control System Upgrade

Upgrading the control system on old PCT machines is by far the most common upgrade we perform. We typically find that PCT machines are, for the most part, mechanically serviceable, but that control components are obsolete (especially PLCs and motor controllers). A control system upgrade could take the form of replacing only key components that are obsolete, or it could be a full control system replacement, which involves completely new electrical enclosures, HMI panels and machine switches & sensors. Control upgrades are normally completed on site within 3 to 10 days, depending upon the scope of work being undertaken.

Benefits of upgrading the control system on old PCT Ltd coilers;

- Eliminates potentially long down time due to the failure of an obsolete component

- Extends the useful live of PCT Ltd machines by 10 to 12 years

- Enables remote monitoring, diagnostics and remote software updates by PCD engineers

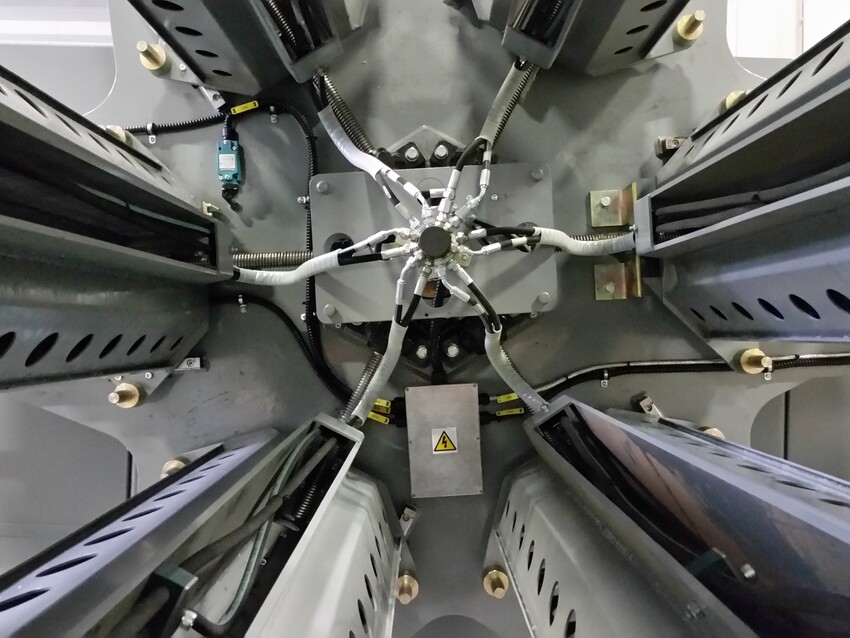

Technology Upgrades

Technology upgrades for PCT automatic coilers originally designed for use with small bore pipe (up to 40mm), including;

- Pipe length measurement upgrade to laser measurement for higher cut-to-length accuracy.

- Laser sensor measurement of coil inner diameter setting, which is more accurate and more reliable than the original LVDT system.

- Pneumatic system for operating pipe feeder tilt and feeder extension, which is more reliable than original electrical actuator systems.